Ondrej Prusa, a 26-year old former DJ, has an enviable problem: his firm making three-dimensional printers is growing so fast he had to install a car-sized diesel generator to his downtown Prague plant to ease burden on the power network.

Prusa became interested in printing in his DJ era when he needed to create sound controllers. He made adjustments to freely-available designs, and eventually set up his business.

Prusa’s office is packed with colourful print examples, from small Buddha statues to turbine models with moving parts and a T-Rex skeleton standing around a metre tall, assembled from printed parts.

Demand for Prusa Research desktop printers, used by enthusiasts, schools and small businesses in 90 countries, has risen to 3,000 a month from the low hundreds a year ago.

“In the whole year of 2015, we made a revenue of 25 million Czech crowns ($ 1 million), which in December of 2016 we are doing in just ten days, which is kind of crazy,” Prusa, 26, told Reuters.

The firm now employs about 80 people and has three printing farms, or rooms where dozens of printers make parts for their own clones. About a third of the parts are made by the printers themselves.

Prusa said he needed no investors as his firm is generating enough cash to push ahead.

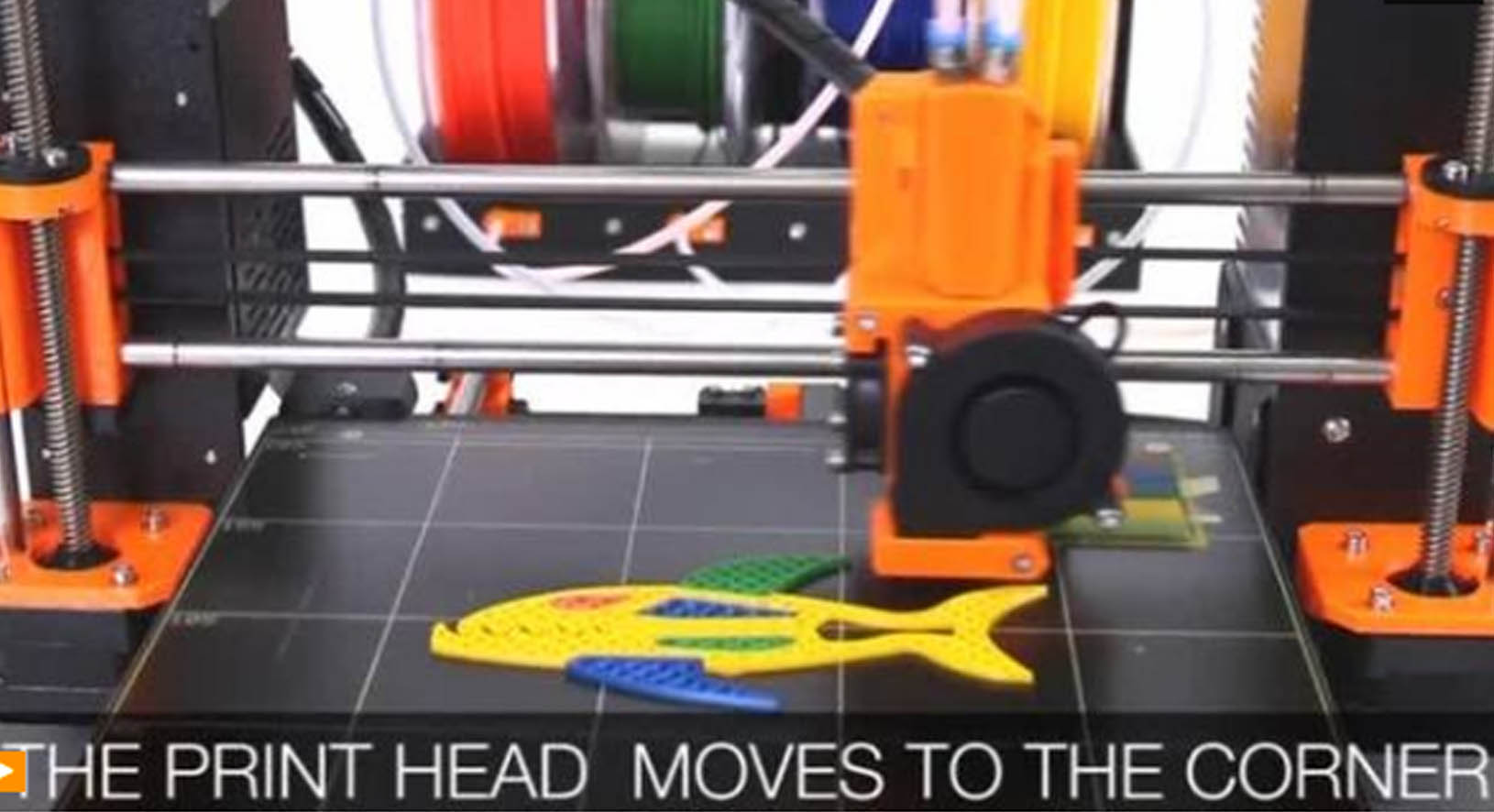

This year, Prusa Research developed and brought to market a 3D printer with an innovative printing head, allowing for the use of four different materials or colours simultaneously.

“Next year we plan to broaden our printer range for more professional users and probably by the end of the year even for educational users, to have basically three printers,” he said.

The growth, spurred by the new Original Prusa i3 MK2, which won favourable ratings by the do-it-yourself community, could put Prusa among the worlds’ leading producers in the desktop printer segment.

Prusa’s machine can print objects to the size of 25x21x20 centimetres, from a range of colourful plastic materials, heated and fed through a nozzle.

“There will not be revolution in the FTM printers, there will be evolution, but most of it will be making it simpler to use,” Prusa said.

Unlike many competing machines, many Prusa’s printers come in kit form rather than assembled. They are based on open-source software that allows others to replicate the design. – (REUTERS)